With the block and head cleaned and inspected, lay down the new head gasket and place the head carefully on to the engine block, lining up the 2 dowels on top of the block. The 5 rear pushrods were set-up the same way as before when we removed the head [This is for Thomas school buses only]

With the block and head cleaned and inspected, lay down the new head gasket and place the head carefully on to the engine block, lining up the 2 dowels on top of the block. The 5 rear pushrods were set-up the same way as before when we removed the head [This is for Thomas school buses only]

The exhaust manifold was left off to allow an even lift with the hoist. There are 26 head bolts in total and they must be checked for pitting and bolt stretch. The head gasket kit comes with a guage that you can check each head bolt with. If the bolt hits bottom on the guage this means the threads have been stretched out. These head bolts must be discarded.

Apply a light film of engine oil on the head bolt threads and install them in the head bolt holes. Torque each head bolt to 52 ft. lbs. starting from the middle and working your way out in a circular motion. Re-torque head bolts a second time.

Torque the 14 LONG head bolts in the middle to 105 ft. lbs. Recheck torque

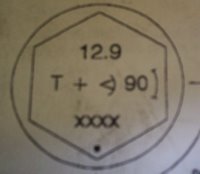

Cummins uses a torque and turn method that works well to compensate for thread stretch and gives a more accurate final torque. The top of each head bolt has the above markings signifying a torque and turn head bolt.

Cummins uses a torque and turn method that works well to compensate for thread stretch and gives a more accurate final torque. The top of each head bolt has the above markings signifying a torque and turn head bolt.

Once the head bolts have been torqued to specs. each head bolt must be advanced another 90 degrees. Just mark a spot on top of the head and turn each head bolt one and a half hexes since each hex is 60 degrees. The head bolt is pre-marked with a reference point as shown above.

When the head bolts are finally torqued, the injectors, fuel lines, rocker arms/pushrods and intake manifold can be installed. Valve adjustment comes next.............

No comments :

Post a Comment